Double-Acting Hydraulic Cylinder

(To be removed) Hydraulic actuator exerting force in both directions

The Hydraulics (Isothermal) library will be removed in a future release. Use the Isothermal Liquid library instead. (since R2020a)

For more information on updating your models, see Upgrading Hydraulic Models to Use Isothermal Liquid Blocks.

Libraries:

Simscape /

Fluids /

Hydraulics (Isothermal) /

Hydraulic Cylinders

Description

The Double-Acting Hydraulic Cylinder block models a device that converts hydraulic energy into mechanical energy in the form of translational motion. Hydraulic fluid pumped under pressure into one of the two cylinder chambers forces the piston to move and exert force on the cylinder rod. Double-acting cylinders transfer force and motion in both directions.

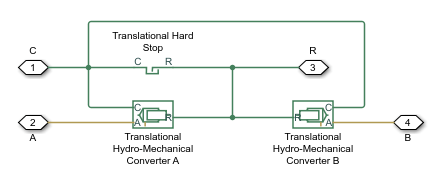

Connections R and C are mechanical translational conserving ports corresponding to the cylinder rod and cylinder clamping structure, respectively. Connections A and B are hydraulic conserving ports. Port A is connected to converter A and port B is connected to converter B.

The energy through hydraulic port A or B is directed to the appropriate Translational Hydro-Mechanical Converter block. The converter transforms hydraulic energy into mechanical energy and accounts for the fluid compressibility in the cylinder chamber. The rod motion is limited with the mechanical Translational Hard Stop block in such a way that the rod can travel only between cylinder caps.

Displacement

The piston displacement is measured as the position at port R

relative to port C. The Cylinder orientation

identifies the direction of piston displacement. The piston displacement is neutral, or

0, when the chamber A volume is equal to the chamber dead volume. When

displacement is received as an input, ensure that the derivative of the position is equal to

the piston velocity. This is automatically the case when the input is received from a Translational Multibody Interface block connection to a

Simscape Multibody joint.

Composite Structure

The model of the cylinder is built of Simscape™ Foundation library blocks. The schematic diagram of the model is shown below.

Assumptions and Limitations

No leakage, internal or external, is taken into account.

No loading on piston rod, such as inertia, friction, spring, and so on, is taken into account. If necessary, you can easily add them by connecting an appropriate building block to cylinder port R.